Boiler Safety Components Explained: Auto Air Vents, Pressure Relief & Safety Valves

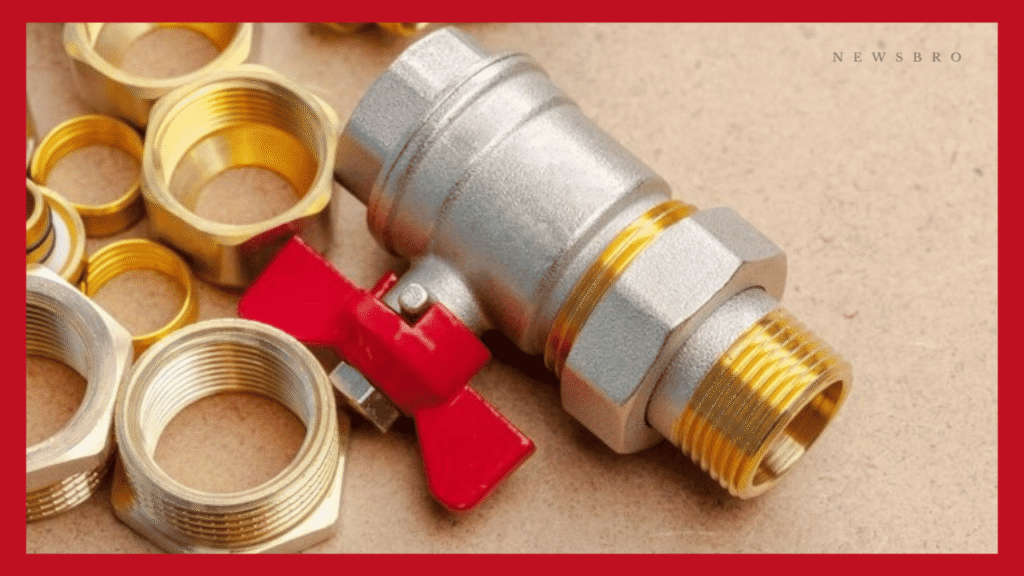

Smaller, overlooked components often have the biggest impact on boiler performance and household safety. Auto air vents, pressure relief valves (PRVs), and safety valves are three essential parts that quietly ensure your boiler operates safely and efficiently every day. If you’re a Gas Safe engineer, property manager, or hands-on homeowner, understanding these components will help you troubleshoot issues early, maintain system health, and avoid costly repairs.

What These Components Mean for Your Heating System

A modern central heating system is a closed-loop system, meaning the water circulating through your radiators and pipework is sealed inside. As water heats up, it expands and releases air. Over time, if not properly managed, this air can cause blockages, reduce efficiency, and even damage your boiler.

- Auto Air Vents automatically release trapped air from your heating system. Trapped air causes cold spots on radiators, noise within the system, and inefficient heating.

- Pressure Relief Valves (PRVs): These valves monitor system pressure and release excess water if pressure rises above a safe limit (typically 3 bar). They prevent pipework damage and protect internal boiler components like the heat exchanger.

- Safety Valves: Often working alongside the PRV, safety valves provide a fail-safe by releasing pressure if the PRV fails or cannot cope with a pressure spike.

These components maintain system balance, prevent pressure build-up, and ensure consistent, reliable heat delivery throughout your home.

Common Problems & Early Warning Signs

Many heating issues can be traced back to faulty air vents or pressure relief components. Here are several common symptoms to be aware of:

- Gurgling or banging noises from your boiler or radiators — often caused by trapped air

- Leaking PRV discharge pipe — indicates the valve has opened and may not have resealed

- Frequent pressure drops even after topping up — could be due to a faulty air vent or PRV leak

- Radiators not heating evenly — a sign of airlocks

- Rust or corrosion around vent or valve locations

While these issues might initially seem minor, ignoring them can lead to pump strain, Boiler Relief Valve failure, system inefficiency, or boiler lockout.

Key Benefits of High-Quality Valves

Choosing high-performance or remanufactured valves offers tangible advantages:

- Maintain Safe Operating Pressure — prevents over-pressurisation and damage

- Improve System Efficiency — air-free systems heat faster and run more smoothly

- Protect Key Boiler Components — by relieving pressure on sensitive parts

- Automatic Functionality — reduces the need for manual venting

- BSI-compliant refurbished options — rigorously tested for safety and reliability

- Compatible with top boiler brands — Worcester, Ideal, Vaillant, Baxi, and more

At NBS, all remanufactured valves and vents undergo stringent testing and include a 12-month warranty.

Expert Insight

“Auto air vents are simple but essential. If you’re constantly bleeding radiators, it might be time to check the vent—it could be stuck or blocked.” — Technical Support Manager, NBS

“PRVs should never be ignored. If yours is dripping, it’s telling you there’s a bigger issue, like a faulty expansion vessel or pressure imbalance. Replacement is often a quick fix that prevents serious damage.” — Heating Engineer, Durham

When to Replace vs When to Maintain

Replace If:

- The PRV or safety valve is leaking from the outlet pipe, even under normal pressure

- The auto air vent is wet, rusty, or visibly damaged

- The system frequently loses pressure without an apparent leak

- Radiators remain cold after bleeding

Maintain If:

- The valve is functioning but has minor debris or dirt — a careful clean may restore performance

- You hear hissing but no water leakage — air release is normal

- You are conducting an annual service and inspecting all components

Isolate and depressurise the system before attempting any replacement. Use only compatible parts and follow the manufacturer’s fitting guidelines.

Maintenance Tips for System Safety

- Inspect valves every 6–12 months for signs of wear or corrosion

- Test PRVs during annual servicing to confirm they’re responsive

- Monitor boiler pressure — it should read around 1.0–1.5 bar when cold

- Top up inhibitor regularly to prevent scale and corrosion

- Bleed radiators if air returns after vent replacement — the issue may not be fully resolved

Preventative maintenance is always cheaper and safer than emergency callouts.

FAQs

How long should a pressure relief valve last? Typically 5–10 years depending on water quality, system pressure, and use.

Why is my PRV leaking water? It’s likely done its job but didn’t reseal properly. Replace it to prevent water loss and pressure issues.

Can I replace a valve or vent myself? If you’re confident and the boiler is out of warranty, yes. But for safety, we always recommend using a Gas Safe engineer.

What’s the difference between a PRV and a safety valve? PRVs operate under normal conditions to regulate pressure. Safety valves are a backup that kick in if the PRV fails.

Do refurbished valves work as well as new ones? Yes. Ours are tested to BSI standards and carry a 12-month guarantee. They’re cost-effective and environmentally friendly.